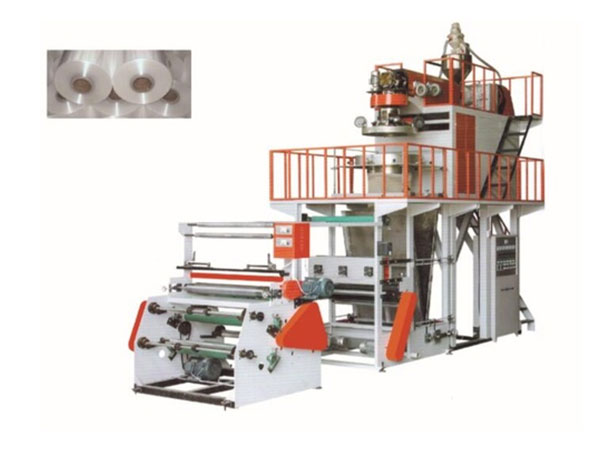

How to judge the blow-up ratio of film blowing machine

This article tells you what is the blow-up ratio of the film blowing machine, what are the methods to judge it, and how to control the blow-up ratio.

The blow-up ratio (or blow-out ratio) of the film blowing machine refers to the ratio of the diameter of the film tube after expansion to the diameter of the mold. It is an important indicator to measure the expansion of bubbles during the film production process. The blow-up ratio determines a series of key qualities such as thickness distribution, tensile properties, and transparency of the film.

The method to calculate the blow-up ratio is simple, just measure the diameter of the film tube and the diameter of the mold. The specific formula is as follows:

Blowing ratio = membrane tube diameter ÷ mold diameter

The film blowing machine manufacturer will give you an example. If the mold diameter is 100 mm and the film tube diameter is 200 mm, the blowing ratio is 2:1.

How to judge the blow-up ratio

The blowing ratio has an important impact on the physical and mechanical properties of the membrane tube. Therefore, in the production process, it is very important to correctly judge the blow-up ratio. The following are several commonly used judgment methods:

1. Direct reading method

The direct reading method is the most basic method for judging the inflation ratio. During the production process, infrared or laser interferometers are set up to observe the film tube diameter and mold diameter in real time, and then calculate the blow-up ratio.

2. Pressure method

Based on the relationship between the inflation ratio, the internal air pressure of the membrane tube, and the external air pressure, the inflation ratio can be determined by measuring the air pressure difference. Generally speaking, the higher the inflation ratio, the higher the air pressure inside the membrane tube and the higher the external air pressure.

3. Periodic method

The periodic method is a method of calculating the blow-up ratio by measuring the difference in length and width of the film. Under certain temperature and pressure, the periodic method can provide very accurate inflation ratio data.

In addition, there are some auxiliary means to determine the blowing ratio, such as film tube position monitoring, automatic control of inductive film blowing machines, etc.

How to control the inflation ratio

Correctly mastering the method of judging the blow-up ratio will help promptly identify problems in the production process and ensure the stability and improvement of film quality. For different production situations, the following methods can be used to control the blowing ratio:

1. Adjust the material ratio

The material ratio will affect the blowing ratio, and the blowing ratio can be controlled by adjusting the ratio of raw materials or adding additives.

2. Adjust membrane tube temperature

During the film production process, adjusting the temperature of the film tube can promote the diffusion of bubbles, thereby achieving control of the inflation ratio.

3. Adjust cooling method

The film inflation ratio can be adjusted by changing the cooling method of the film tube, such as using spray cooling or adding an appropriate amount of coolant.

In short, correctly mastering the judgment method and control skills of the blow-up ratio is crucial for plastic film production. Film blowing machine manufacturers can choose a judgment method that suits them based on specific circumstances, and take corresponding control measures to optimize the production process and improve product quality.