What is a film blowing machine?

Plastic films can be seen everywhere in our lives, but how did plastic films come from? We have to mention the blown film machine at this time.

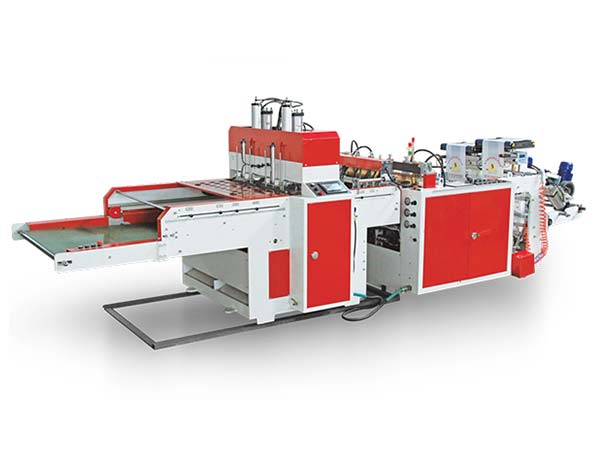

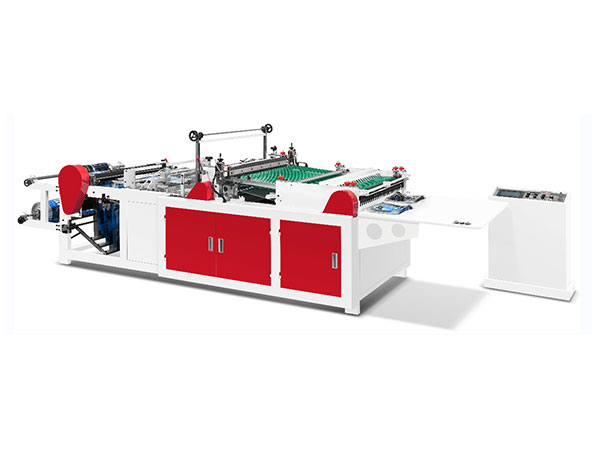

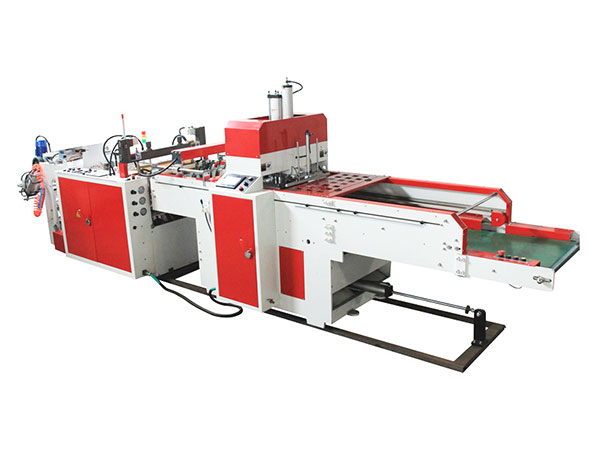

The film blowing machine is a machine that heats and melts plastic particles and then blows them into a film. It is mainly composed of an extruder, a die head, a cooling device, a traction roller, and a winding device.

The work of a blown film machine usually includes the following steps:

1. Plastic granules enter the extruder and are transformed into molten plastic through heating and melting.

2. Molten plastic is extruded through a die to form a circular film tube.

3. At the outlet of the die, inject high-pressure air into the film tube to make it expand and maintain the shape of the film tube.

4. The film tube passes through the cooling device to make it cool and solidify rapidly.

5. The cooled film passes through traction rollers, stretched and shaped to control the width and thickness of the film.

6. Finally, the film is taken up by a winding device to form a finished roll, which is ready for the next step of processing or packaging.

The film blowing machine can adjust the temperature, extrusion speed, cooling method and other parameters of the extruder according to the production needs to control the thickness, width, transparency, strength and other characteristics of the film.

What type of film can the blown film machine produce?

1. LDPE film: Low-density polyethylene (LDPE) film has good flexibility and transparency, and is often used in food packaging, shopping bags, garbage bags and other applications.

2. LLDPE film: Linear low density polyethylene (LLDPE) film has high tensile strength and tear strength and is widely used in packaging and industrial applications.

3. HDPE film: High-density polyethylene (HDPE) film has high hardness and rigidity, and is often used in applications such as disposable gloves and soil covering films.

4. PP film: Polypropylene (PP) film has high tensile strength and heat resistance, and is widely used in packaging, stationery, engineering and other fields.

5. PVC film: Polyvinyl chloride (PVC) film has good transparency and chemical stability, and is often used in curtains, carpets, water pipes and other applications.

6. EVA film: Ethylene vinyl acetate copolymer (EVA) film has good flexibility and weather resistance, and is used in solar panels, packaging and other fields.

In addition, the blown film machine can also produce multi-layer composite films, by extruding and compounding laminated sheets of different materials to give the film specific properties, such as gas barrier, freshness preservation, etc.